Third generation farmer Derrick Nordberg of Cowiche Creek Brewing Company takes over this week’s #ROOTCAM to share some insight into the multi-tasking life of brewing. Thanks, Derrick!

Being the brewer at Cowiche Creek Brewing Company often means handling multiple tasks at the same time. This day was no exception. While brewing I was also running the tap room on a somewhat busy Saturday afternoon as well as preparing to leave town for the first time since we had started this business. At certain times you are rushing back and forth between cleaning grain out of the mash tun, running a sanitization loop on a destination fermenter, filling the boil up with Yakima Valley grown hops, and filling customer’s glasses up with the cold finished product all at the same time. It is a hot and steamy nine hour job but also a good workout that burns a few calories from tasting all that delicious IPA.

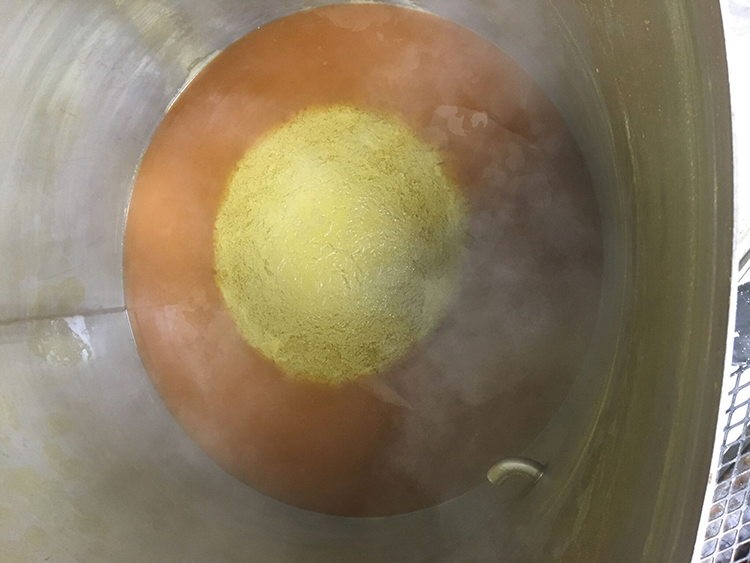

Brew days start with harvesting yeast from a previous batch of beer, grain milling, and cooking those grains at around 148 °F. The next six hours consists of monitoring and adjusting temperatures and levels on 5 different vessels, moving the sugary liquid called wort through the stages of the brewing process while adding ingredients at timed intervals, and cleaning and sanitizing everything twice. Most of that time is spent on the latter which is why we call ourselves very observant janitors.

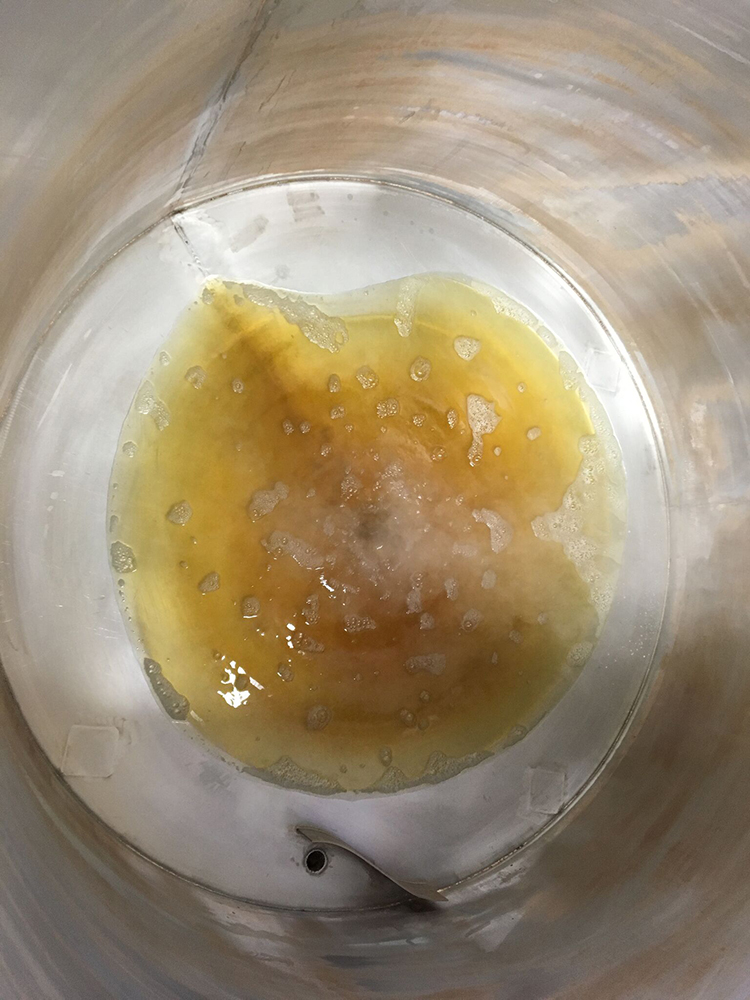

Once the beer has been made, the yeast have begun eating the sugar as evidenced by the bubbles forming in the blow off bucket, and the customers have all gone home there are still a couple hours of cleaning left. From the bathrooms to the heat exchanger, everything being cleaned is majority of what goes on inside this building. That and of course customers enjoying cold pints that are a result of all this work.