On a frozen morning in Selah, Aileen and I drive up a short hill off Selah Loop Road. Getting out of the car, we are greeted by a dog named Hope. It’s a sign. We’re hoping to see some mushrooms growing this morning here at J&M Gourmet Mushrooms. We spot Michael Bennett and he motions us to walk up a little further to where he’s standing and guides us into his shop. Michael grows mushrooms all over his property, but this time of year for obvious reasons, it’s indoors.

Michael is a fascinating guy. Standing in the shop in his Carhartt overalls and long white ponytail, Hope circling at his feet, he launches into mushroom talk. Clearly a passion he is incredibly knowledgeable about. Not knowing anything about growing mushrooms, I ask him to slow down and take us back to square one. He tells us that like a tree root running through a medium like dirt and absorbing nutrients to send up into the tree so it can bear fruit and pass seeds along, for mushrooms, mycelium runs through a medium like straw absorbing nutrients and sends up mushrooms—a process called pinning—for passing spores along. As a mushroom grower, what he does is create a medium for growth, inoculate it with with mycelium spawn, and facilitate the correct conditions that will allow it to proliferate so that pinning can take place and mushrooms will grow.

Sounds pretty straight forward but it’s not as easy as it sounds, as Micheal learned about seven years ago when his mushroom growing days were just getting started. After building Yakima’s first straw bale structure house, he had an excess of straw in his possession. Someone suggested growing mushrooms and he was intrigued so he looked into it. Inoculate, drill drain holes, mist, and wait for mushrooms—what a great retirement setup! It failed. Not one to give up easily, he wanted to know more.

Sounds pretty straight forward but it’s not as easy as it sounds, as Micheal learned about seven years ago when his mushroom growing days were just getting started. After building Yakima’s first straw bale structure house, he had an excess of straw in his possession. Someone suggested growing mushrooms and he was intrigued so he looked into it. Inoculate, drill drain holes, mist, and wait for mushrooms—what a great retirement setup! It failed. Not one to give up easily, he wanted to know more.

After attending a two-day school through Fungi Perfecti in Olympia, he learned everything he did wrong and that the desert climate of the Yakima Valley isn’t ideal for mushroom growth. He was told that it wouldn’t work unless he was stubborn and attentive, and as luck would have it, those are two qualities Michael says he has more than enough of. “You don’t control anything, it’s about looking for minute changes and using those windows of opportunity.” It’s clear it’s the challenge that makes it worthwhile for him. After some trial and error, he had success and, partnered with his wife Judy and Terry Travis, J&M Mushroom was born.

After attending a two-day school through Fungi Perfecti in Olympia, he learned everything he did wrong and that the desert climate of the Yakima Valley isn’t ideal for mushroom growth. He was told that it wouldn’t work unless he was stubborn and attentive, and as luck would have it, those are two qualities Michael says he has more than enough of. “You don’t control anything, it’s about looking for minute changes and using those windows of opportunity.” It’s clear it’s the challenge that makes it worthwhile for him. After some trial and error, he had success and, partnered with his wife Judy and Terry Travis, J&M Mushroom was born.

He walks us through his process and takes us over to a room with several barrels of submerged straw. When concocting growth medium, it needs to be as clean as possible to prevent contamination from bacteria or other fungi. Contamination is one of the biggest problems to deal with in mushroom farming. Michael cold pasteurizes his straw by submerging it in water and weighting it down so that all the oxygen dependent organisms die off. Anything left that can live without oxygen dies as soon as it is brought out of the water and into the air, leaving clean straw.

He combines this with recycled cardboard (cellulose), which he currently gets from Zirkle Fruit, and depending on the mushroom type, can add other things as well if the mycelium will love it. The straw he shows us today was sprayed with trub, which is the spent hop and grain particles leftover from the beer brewing process that he sources from local breweries. Oyster mushrooms adore it. This mix is inoculated with spawn and bagged into 40-50 lb columns and perforated with holes for the eventual pinning.

He combines this with recycled cardboard (cellulose), which he currently gets from Zirkle Fruit, and depending on the mushroom type, can add other things as well if the mycelium will love it. The straw he shows us today was sprayed with trub, which is the spent hop and grain particles leftover from the beer brewing process that he sources from local breweries. Oyster mushrooms adore it. This mix is inoculated with spawn and bagged into 40-50 lb columns and perforated with holes for the eventual pinning.

The next room over is the growing chamber that Michael built to better control temperature and humidity, and was totally amazing to walk through. Diffused light comes through the ceiling, and the wet floor shines with humidity. It’s not hot, thick or swampy humidity, but rather smells cool, earthy and dense. Optimum temperature is 50 degrees which has been hard to maintain this cold winter. The columns of inoculated straw hang in rows here while the mycelium takes time to develop causing the mushrooms to grow (if there is no contamination. If there is, it’s scrapped and the process has to start all over again).

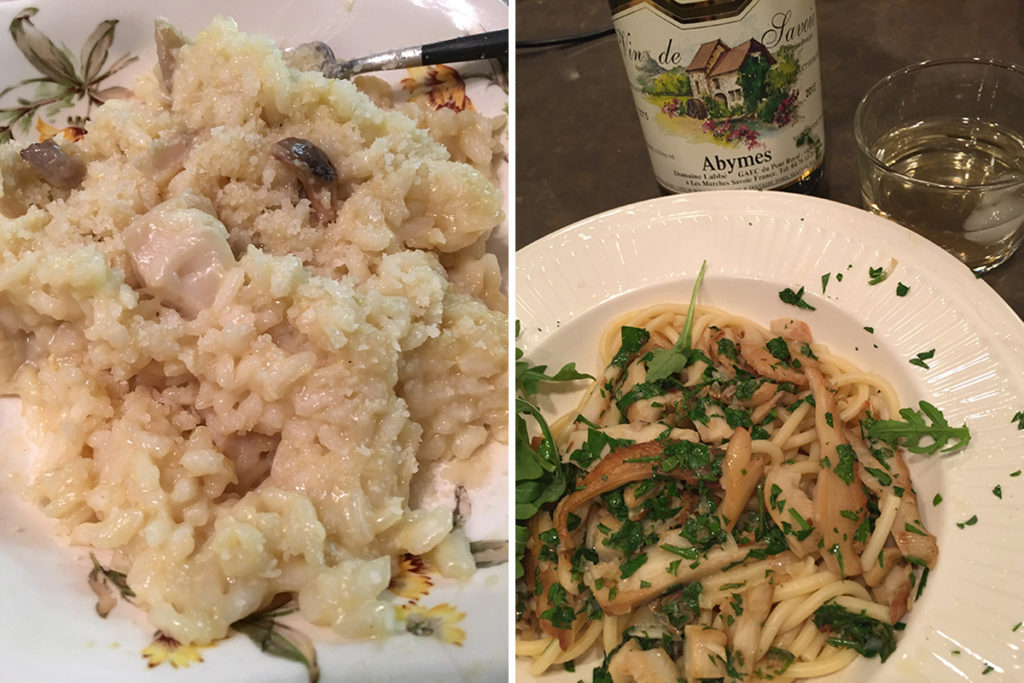

We can see the pinning everywhere. First, tiny heads or clusters of heads poke through the perforation, then they keep on growing into the lovely giants that us mushroom lovers lick our lips for. We watch as he harvests a basket of Polar White Oyster mushrooms and a few Grey Doves, the risotto ai funghi recipe blooming in my mind.

Chefs and kitchens all over are in the know. Zesta Cucina, who Michael was picking for today, Birchfield Manor, Carousel, Cowiche Canyon Kitchen, the Yakima Country Club, Guerra’s Gourmet Catering, Prosser’s Wine O’Clock, and Tagaris in Richland are just a few we spot on his buyers list. Mushrooms are so versatile in the kitchen, there are an infinite amount of ways to be creative and make something delicious. To get them fresh and local is an outstanding bonus. He sells to the public as well, and Aileen and I walk away with a pound apiece.*

We both learned so much. It felt like part mycological edification, part life philosophy lesson. What Michael really loves about what he’s doing is that he’s still learning things everyday. He emphasizes again how he has no control, but there are ways to work within what you have available to you. There is always a challenge to think through, mistakes can be learned from, and there is a never ending list of new things to try. He works very hard and feels very blessed. In the warmer weather, he has mushrooms growing everywhere and has about seven varieties he grows well and always has an eye out to trying more. I think we’ll just have to come back.

*I did make risotto ai funghi later that night, while Aileen went with a simple pasta with butter, garlic, shallots, Italian parsley, and arugula . . . which resulted in two happy families.

*I did make risotto ai funghi later that night, while Aileen went with a simple pasta with butter, garlic, shallots, Italian parsley, and arugula . . . which resulted in two happy families.

J&M Gourmet Mushrooms is located at 247 Collins Rd. Selah, WA.

A giant thanks to Michael Bennett who was so generous with his time and patient with his explanations. We were blown away!

This is a fascinating article. I learned a lot and really enjoyed it. The excellent photos clarified the explanations.

Hmm. Michael sprays some? mushrooms with trub….left over grain particles from the beer making process. Malt (barley)???? Does the end product contain gluten? Barley is used in making most beers. It is a source of gluten. Just thinking.